|

|

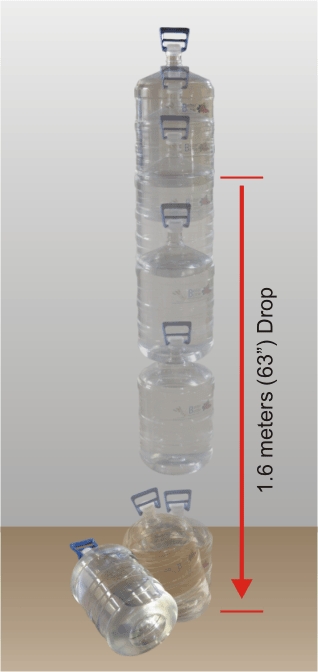

Drop Test – Amazing, but don't do this on purpose

For the BetterBottle Drop Test, a carboy is filled with ~21°C water to approximately 90% capacity, capped with an LDPE single-use closure, and dropped, bottom down, on a smooth concrete floor from a height of 1.6 meters (5 feet 3 inches). If a carboy shows no visible signs of rupture after five (5) drops, it is given a passing grade; however, it is not uncommon for carboys to withstand being dropped more than ten times.

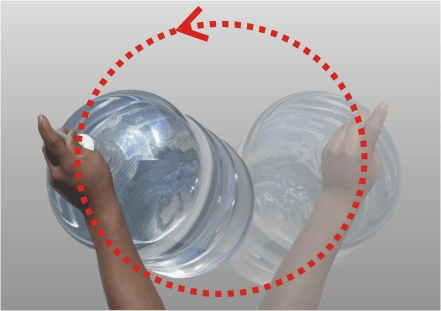

Edge Roll Test – Over 1 KM (0.62 miles) of rolling

For the BetterBottle Edge Roll Test, a carboy is filled with ~21°C water to approximately 90% capacity, fitted with a vented closure that is equipped with a swivel handle, tilted at about a 25° angle, and rolled round and round over 1300 times, the equivalent of more than 1 kilometer (2/3 mile), on a smooth concrete floor. If a carboy shows no visible signs of cracking prior to the end of the test, it is given a passing grade.

Important: This test is impressive; however, when swirling a carboy, a tennis ball should be placed under the punt of the carboy to prevent its edge from contacting the surface and being repeatedly flexed. There is no point in pushing limits.

|