|

|||||

|

|

|

Introduction | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Water Purity - A Few Words of Caution The purity of tap water should not be taken for granted. Essentially all tap water, whether it is water from a private well or municipal water that has been treated with biocides, may contain significant concentrations of viable microorganisms as well as organic and inorganic substances that may have a detrimental impact on winemaking or brewing. And home water treatment systems can further complicate the situation. Microorganisms are likely to flourish on the large surface areas provided by beds of activated carbon and water softener exchange resins. These microorganisms are unlikely to pose a health problem under most circumstances and they can break down many harmful organic contaminants; however, they can also spoil an otherwise excellent batch of wine or beer. Furthermore, water softeners exchange salt ions that carry two positive charges and cause water hardness (e.g., calcium [Ca++], magnesium [Mg++], etc.) for twice as many salt ions that carry a single positive charge (e.g., sodium [Na+] or potassium [K+]); thereby, making the softened water significantly more salty than the hard water. Conclusion: If you are just getting started with home winemaking or home brewing and you do not yet have experience with a particular source of water, use commercially bottled drinking water, RO water, or distilled water for final rinsing and to dilute juices in order to minimize the number of variables and to gain a level of confidence. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Water Temperature

- Very Hot Water is Dangerous,

Potentially Destructive, and Unnecessary.

BetterBottle PET carboys are rated up to 60°C (140°F), the highest temperature considered acceptable for residential hot water heaters, and BetterBottle fittings are rated up to 75° C (167°F), the highest temperature for the great majority of residential dishwashers. Water above 52°C (125°F) is generally considered to be dangerously hot and is not necessary for effective washing or sanitizing. The following chart, taken from the University of Michigan, Pediatric Advisor 2006, shows just how dangerous hot water can be.1 At temperatures above 60°C (140°F), it may not be possible to react quickly enough to avoid a serious burn.

The European Guidelines for

Control and Prevention of Travel Associated Legionnaires'

Disease recommends that hot water should be stored at 60°C (140

°F) to prevent the growth of Legionella bacteria in hot water

storage tanks, but water exiting faucets should not exceed 52°C

(125°F).2 Important Note - The belief that The United States Food and Drug Administration (FDA) Good Manufacturing Practices Manual requires washing dishes or bottles at temperatures of 77°C-93°C (170°F-200°F) is based on misinterpretation. Subpart E, Section d of the Manual states, "Sanitizing operations, including those performed by chemical means or by any other means such as circulation of live steam or hot water, shall be adequate to effect sanitization of the intended product water-contact surfaces and any other critical area." 5 Steam, hot water, and chemical sanitizers, including ozone, are listed as options and the operative phrase is, "adequate to effect sanitization" - if the process is effective, it is acceptable. The International Bottled Water Association (IBWA) Plant Technical Reference Manual recommends a pragmatic approach to washing carboys, based on verification, and points out that manufacturers of polycarbonate (PC), resins recommend the use of non-caustic cleaning agents and a wash temperature of no more than 130°F.6 PC carboys are prone to developing Environmental Stress Cracking (See Rinsing below) and release significantly more of the toxin bisphenol-A (BPA) when washed with alkaline detergents at elevated temperatures. For more about BPA see Purity/Safety at the left of this page. What is the point to using very hot water when:

1 Burn Safety: Hot Water Temperature. University of Michigan, Pediatric Advisor 2006 Retrieved on 03/15/2008. 2 European Guidelines for Control and Prevention of Travel Associated Legionnaires' Disease. European Working Group for Legionella Infections (Jan 2005). Retrieved on 03/15/2008. 3 Food Service Protection. BC Centre for Disease Control 655 12th Avenue W, Vancouver, BC V5Z 4R4. Retrieved on 03/15/2008. 4 Sterilization (microbiology). From Wikipedia, the free encyclopedia. Retrieved on 03/15/2008. 5United States Food and Drug Administration (FDA) Good Manufacturing Practices Manual - Part 129 - Process and Bottling of Bottled Drinking Water Subpart E - Production and Process Controls (1995) - PDF 6 IBWA Plant Technical Reference Manual, International Bottled Water Association, 1700 Diagonal Road, Alexandria, VA 22314 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The fact that BetterBottle carboys and

fittings are amazingly stain resistant is an excellent indicator of

the fact that they do not absorb substances from wine or beer and

from washing or sanitizing solutions to a significant degree (see

Flavor Scalping at the left of this page). This is an extremely

important advantage.

Just imagine washing two sticky soup bowls, one made of BetterBottle PET and the other of a porous material. Which one will be easier to wash and rinse so the next person to use the bowl will not have off flavors and detergent in their soup - night and day, right? As a general rule, avoid using porous materials, especially those that stain easily or retain odors. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Rinsing - Absolutely Essential This section about rinsing is placed before the Washing, Sanitizing, and Drying sections, because it deals with issues that are common to these other sections. The most convenient way to rinse a BetterBottle carboy is to hold it upside down and direct a jet of water against its bottom, using a nozzle that extends far enough into the neck to prevent the outflow of water from blocking the water jet. A pistol-grip garden hose nozzle will work and there are many commercially available bottle rinsing attachments for sink faucets. A carboy fitted with a Racking Adapter can also be rinsed through the adapter, which can be turned to direct the jet of water against the bottom. BetterBottle fittings should be rinsed and dried while they are still disassembled after washing or sanitizing. Rinsing with tap water should not pose a problem when carboys and fittings are to be stored; however, consider using some commercially bottled, ozonated, drinking water (see Water Purity above) as a rinse following a sanitization done just prior to starting a fermentation.

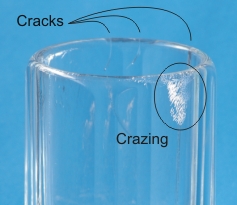

Compared to other materials (including glass), the special PETs from which BetterBottle carboys and fittings are made have exceptional resistance to attack by the aggressive commercial detergents and sanitizers traditionally used in home winemaking or brewing; however, these PETs are not expected to be totally resistant to attack under all conditions. Caustic Stress Cracking (CSC) is the term describing a complex, and often difficult to predict , process by which the chemical bonds of polymer molecules, ester bonds in the case of PETs, are more prone to chemical breakage when they are under stress from bending or stretch.1, 2 Metallurgists typically use the term Stress Corrosion Cracking or Environmental Stress Fracture to describe this type of failure in metals. The chemistry is complex, but the practical implications are not. A piece of PET from the wall of a BetterBottle carboy can withstand being repeatedly and sharply bent an astonishing number of times without cracking. However, placing a sharply bent piece of the PET in a concentrated solution of strong acid or strong caustic will, given enough time, cause cracks to develop along the bend, even though the rest of the piece may not show any signs of damage. Conclusion: As a precaution, rinse all winemaking and brewing equipment, not just BetterBottle equipment, thoroughly after washing or sanitizing and store it dry. Be certain that internal component parts of equipment such as valves, air locks, or pumps (parts that may not dry if equipment is assembled) are completely dry prior to storage. 1 Environmental stress cracking. From Wikipedia, the free encyclopedia. (Accessed 05/15/2010) 2 Moskala,E.J. and Jones, M. Evaluating Environmental Stress Cracking of Medical Plastics. Medical Plastics and Biomaterials. May, 1998 (Accessed 05/15/2010) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Washing - Easy

Does It

BetterBottle carboys are resistant, but not immune, to attack by very aggressive detergents, which were originally created for use with commercial, stainless steel brewing equipment. As noted in the Material Specs section (see left side of page), strong caustics will damage PET. They also damage other plastics, glass and metals. Manufacturers of laboratory glassware warn against soaking glassware, especially large items made of soft glass (soda lime glass), in caustic solutions.6, 7,8 Use only brand-name detergents that have a good track record. It is terribly important that caustic detergents are diluted according to the manufacturer's recommendations for routine cleaning (i.e., <1% by weight for Five Star PBW*) and contact times should be minimized. Instead of soaking carboys and fittings in high concentrations of detergent for hours and hours, use lower concentrations, smaller volumes of detergent solution, and agitation (it's easy with BetterBottle carboys and fittings). Also, replace fouled detergent solution frequently in order to maintain maximum cleaning efficiency. * A 0.5% solution of Five Star PBW detergent can be made by mixing 5 grams per liter of water or 0.67 oz (19 grams or about a level table spoon) per gallon-US (3.78 liters) of water. Note that a 0.5% solution of PBW will have a pH approaching 12, whch is quite caustic.With the exception of essentially pH neutral, enzyme-enhanced detergents, avoid pouring detergent powders or concentrated liquid detergents into your BetterBottle carboys and then, adding the diluting water as a second step. Also, do not pour caustic detergent powder into a carboy filled with diluting water or into a pot containing BetterBottle fittings. The extremely high concentrations of the detergent close to undisolved powder can cause damage to the PET. Dilute the powders in a bucket and then add the solution to carboys or use it to wash the fittings. Important: Rinse equipment immediately after washing and do not leave equipment standing in spilled detergent solution. As water evaporates, the residual detergent solution will become extraordinarily concentrated, which is a worst case situation for damaging equipment. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fittings - BetterBottle fittings should be disassembled, because disassembly and reassembly is so quick and easy and it will insure effective washing. A soft tooth brush and a small test tube brush or pipe cleaner will help to quickly remove stubborn debris from the surfaces of BetterBottle fittings. Use caution not to scratch the precision, conical, sealing surface of DryTrap air locks or the smooth sealing surfaces of Carboy and Pail Adapters or SimpleFlo valves. Soaking fittings in detergents, particularly caustic detergents is not an effective way to wash the fittings and is not recommended. Also, Remove metal parts when cleaning or sanitizing, to avoid possible corrosion. Tubing - PET-lined tubing can be washed by partially filling it with detergent solution and, with both ends of the tubing sealed, pouring the solution back and forth from one end of the tubing to the other for a few minutes. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Conclusion: BetterBottle recommends using enzyme-enhanced

neutral detergents for washing BetterBottle carboys and fittings. If

you use other types of washing agents, be sure to dilute them in a

bucket to the concentrations recommended by their manufacturers

for routine cleaning and minimize the exposure of your

equipment. Higher concentrations and long contact times should not

be necessary and will likely shorten the useful life of your

equipment. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sanitizing - No Point In Overdoing It The purpose of sanitizing agents is to reduce the number of viable microorganisms to acceptable levels, not to achieve sterility. Sterilization requires aggressive physical (i.e., flaming, autoclaving at 121°C for 15 minutes, radiation, etc.) or chemical (i.e., ethylene oxide, ozone, bleach, hydrogen peroxide, etc.) conditions.1 Winemaking and brewing do not require sterile conditions; however, the numbers of unwanted microorganisms must be kept low or their presence can be detrimental. Sanitizing agents generally require short contact times, typically only a matter of minutes, to be effective. It is unwise to use higher concentrations of sanitizers than recommended by the manufacturers or to leave winemaking or brewing equipment in contact with the solutions any longer than necessary for the reasons described above (see Rinsing and Washing). Storing concentrated stock solutions of sanitizers for long periods in any type of carboy is not recommended. As a general rule, equipment should be sanitized and given a final rinse shortly before use. BetterBottle carboys and fittings are exceptionally resistant to attack by the sanitizers recommended for use in home winemaking or brewing. Also, the special PETs from which BetterBottle carboys and fittings are hydrophobic and non-absorbing (see Flavor Scalping), so sanitizing agents rinse away quickly with a minimum of water. BetterBottle carboys are also so light weight they can be easily rolled and tipped to insure that every surface is exposed to the sanitizing solution, without using a large volume. Between fermentations, BetterBottle fittings should be sanitized at least once while disassembled in order to insure effective sanitization; after all, disassembly and reassembly is quick and easy. Prior to starting a fermentation, ported Carboys and pails can be given a leak test, a final sanitizing, and a rinse, with the Racking Adapters and SimpleFlo valves in place. However, be certain to open and close the valves a number of times while sanitizing and rinsing to permit the sanitizing solution and rinse water to contact all surfaces. PET-lined tubing should be partially filled with sanitizing solution and with both ends of the tubing closed, the solution should be repeatedly poured back and forth from one end of the tubing to the other for long enough to give adequate contact time. A word about flaming - Don't! Obviously, flaming BetterBottle PET carboys or fittings will damage them. For what it is worth, flaming is also very likely to crack the neck of a soft-glass carboy or create strains that will make the neck more likely to crack later. Use a sanitizing agent instead. A 70% solution of ethanol is often used as a wipe-down sanitizer; however, alcohols are not as potent as other sanitizers and require longer contact times in order to be effective. Important Notes:

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

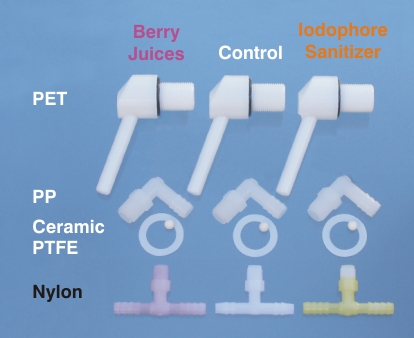

| Challenge Testing With

Sanitizers - From time to time,

random BetterBottle carboys and fittings are challenge tested with

sodium metabisulfite, chlorine bleach, ozone, Five Star Iodophor

sanitizer, Five Star dodecylbenene sulfonic acid sanitizer, and

Selective Micro Tech CLO2 sanitizer, which are

representative of products readily available to home winemakers and

brewers. The concentration of the sanitizing solutions used for

testing are at the upper limits recommended by the manufacturers.

The solutions are initially at ~24° C and permitted to equilibrate

with ambient temperatures. The sanitizer solutions are not

replenished during the tests. Carboys are filled with the solutions

for approximately 2 hours and fittings and their components are left

in the solutions for approximately 1 hour. Effective sanitizing can

usually be accomplished in a matter of minutes.. After exposure, the

carboys and fittings are visually inspected for cracks or other

signs of damage. The carboys are also subjected to the Edge

Roll Test (See Durability). The challenge tests demonstrate that BetterBottle carboys and fittings are quite resistant to sanitizer damage; however, even though the tests have been repeated many times over the years, the test sample is necessarily relatively small in comparison to the number of carboys and fittings sold. It should not be assumed that every BetterBottle carboy and fitting can be subjected to these concentrations of sanitizing agents for longer periods of time or repeatedly, because damage is likely to be cumulative. Nor should it be assumed that other types of PET would yield equivalent results.

1 Hampson, B. Use of ozone for winery and environmental sanitation. Food Science and Nutrition Dept, California Polytechnic State University, San Luis Obispo, CA. 2000 February. (Accessed 05/15/2010). | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Glass is hydrophilic, so water forms a film on the surface and well-cleaned glass carboys may appear to drain dry even though they are not actually dry. BetterBottle carboys are hydrophobic, so small droplets of water will remain on their surfaces when the final rinse water is drained out. If a carboy is to be used immediately, these droplets of water will not be a problem. If a carboy is to be stored, shake it a little to remove some of the residual droplets and set the carboy on its side in a clean, dry area. BetterBottle carboys tend to dry out more quickly when they are placed on their sides than when they are inverted on the sort of stand that is used for draining glass carboys.