| Introduction |

|

The BetterBottle

SimpleFlo™ Valve and Racking Adapters make up the first valve

system that truly addresses the specialized needs of home

winemakers and home brewers. The components are made of an

incredibly tough, proprietary PET that does not stain or impart

flavors and is easily cleaned and sanitized. BetterBottle Racking

Adapters use a Teflon-encapsulated, Viton O-ring to make a clean,

tight seal against the inside wall of carboys and pails, so

the Racking Adapter's screw threads and tightening nut are

outside of the container (see Installation below).

BetterBottle Racking Adapters are also very simple to install and

remove, making thorough cleaning and sanitizing especially easy.

Now, it is possible to rack and bottle professionally, without

siphons or pumps.

General purpose

tank valves are designed in exactly the opposite fashion, with the

seals being made against the outside wall of carboys or pails. This

leaves all the crevices associated with the threads and nuts on the

inside of the container. Such valves are not designed for racking;

they will not drain the last 2 inches (5 cm) of liquid from a carboy

without tipping the carboy and potentially disturbing the sediment

layer, because they cannot be installed any lower. Furthermore, they

are difficult to attach or remove from a carboy, they can be

difficult to disassemble for cleaning and sanitizing, and there is a

good chance they are made of materials that will be damaged by the

detergents and sanitizers used in home winemaking and beer brewing.

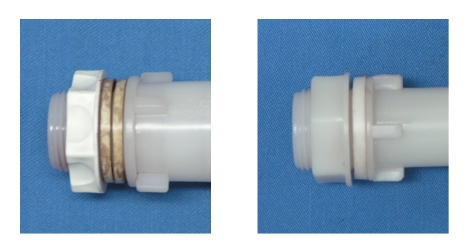

General Purpose Tank

Valves

- They

Seal against the outside walls of carboys and have internal threads

and nuts -

Additional

Information - Use the pop up menus

associated with the SimpleFlo

Valve and Racking Adapter tabs at the left side of this page for random access

to all the specific information relating to the BetterBottle

SimpleFlo valve and Racking Adapters. Scrolling down this page will

access the information for Racking Adapters in sequential fashion.

For materials specifications, please refer to the Technical tab

at the top of this page.

Chemical

Resistance - In general, avoid very

strong caustics, such as KOH and NaOH (lyes), and concentrated

aliphatic ketones (e.g., essence oils). For additional materials

specifications, please refer to the Technical tab

at the top of this page.

|

| Carboy

Racking Adapter |

|

Description

- BetterBottle Carboy Racking Adapters

couple SimpleFlo™ valves to any ported BetterBottle carboy, and the

combination makes professional racking and

bottling quick and easy.

Operation - The

Carboy Racking Adapter uses a Teflon-encapsulated Viton O-ring to

make a tight hydrophobic seal against the inside wall of a

BetterBottle carboy. This very special O-ring also makes it possible

to rotate the body of the Racking Adapter, without the need for

lubrication. Racking is accomplished by simply rotating the Adapter

so the tip of its intake stem is just above the sediment layer,

opening the SimpleFlo valve, and letting gravity go to work - there

is no need for siphons or pumps. During filling and fermentation,

the stem of the Racking Adapter should be tilted slightly downward

(about 3:30 or 8:30) to prevent sediments from settling inside it.

The external pointer makes it possible to adjust the position of the

stem even if the stem cannot be seen through a dark wine or beer.

The Carboy Racking Adapter is especially

popular with winemakers and brewers who ferment on shelves, because

carboys can be racked without having to move them to a surface with

head room for racking canes. For more detailed information about the

use of the Racking Adapter refer to the

How-To Tips tab to the left of this page.

|

|

Installation - The BetterBottle Carboy Racking Adapter has been

designed so it is easy to install and service. Be certain all of the

component parts are installed in the correct order. Do not attempt

to drill ports in unported BetterBottle carboys, because the special

PET from which the carboys are made is very tough and specialized

tools are required to make sufficiently smooth

holes.

|

|

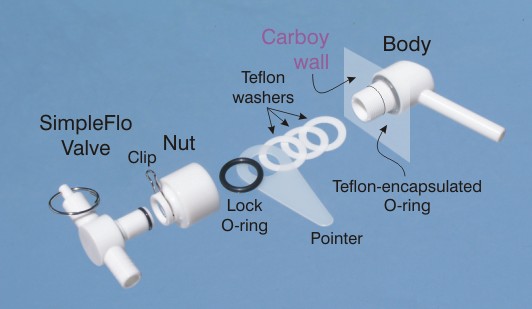

Carboy Racking Adapter

- Sequence of Components -

Note: SimpleFlo Valves are not included as part of

Adapters - order them separately.

|

|

|

Installation in 5 & 6

Gallon Carboys - BetterBottle

makes a plastic installation tube for installing Carboy

Racking Adapters in 5 or 6 gallon BetterBottle carboys (See

images below). In a pinch, it is also possible to use a 50 cm

(20") length of 1/4" diameter steel (plated or stainless) rod

or running thread or a 44 cm (18") length of 3/8" inside

diameter (clearance) rigid tubing, both of which can be

purchased at most hardware stores.

|

|

| 1.

With the Teflon-encapsulated O-ring in place, use a tube

or rod to slide the Racking Adapter body into the neck

of a carboy. |

2.

Guide the threaded portion of the Racking Adapter body

into the hole in the side of the carboy. |

|

|

| 3.

Hold the Racking Adapter body in place with the rod or

tube and install the three Teflon slip washers, the

pointer (if desired), and the locking O-ring in that

order. Apply a little water to the threads and install

the nut. |

4.

Finger tighten the nut, using enough force so the

Racking Adapter makes a good seal and can be

comfortably, but not easily, rotated by hand. A sticky

pad (jar opener) can make tightening easier. Observe the

position of the pointer with respect to the stem of the

Racking Adapter. Assuming the pointer and stem are not

aligned, loosen the nut and reposition the pointer, so

it will line up with the stem when the nut is

re-tightened. Re-tighten the nut. It may be necessary to

repeat this last step a number of times in order to

achieve adequate pressure on the seals and line up the

pointer. |

|

| 5. Slide out the tube or rod and

double check that the Outlet assembly rotates smoothly,

but with enough resistance to indicate a good seal.

Adjust the tightness of the nut as required.

|

Installation in 3 Gallon Carboys-

A rod or tube is not needed to

install a Racking Adapter in a 3 gallon BetterBottle bottle,

because the stem of the outlet will contact the bottom of the

carboy and prevent the Adapter from rotating continuously in

one direction.

- Drop the body of the Racking Adapter,

with the Teflon-encapsulated O-ring in place, into the

bottle and guide the threaded part of the body through the

hole in the side of the bottle with a stiff piece of wire or

something like a small screwdriver inserted through the hole

from outside the bottle.

- Once the thread pokes through the

hole, pull it all the way into the hole and install the

three Teflon slip washers, the pointer (if desired), the

locking O-ring, and the nut in that order. Apply a little

water to the threads and install the nut.

- Finger tighten the nut, using enough

force so the Racking Adapter makes a good seal and can be

comfortably, but not easily, rotated by hand. A sticky pad

(jar opener) can make tightening easier. Observe the

position of the pointer with respect to the stem of the

Racking Adapter. Assuming the pointer and stem are not

aligned, loosen the nut and reposition the pointer, so it

will line up with the stem when the nut is re-tightened.

Re-tighten the nut. It may be necessary to repeat this last

step a number of times in order to achieve adequate pressure

on the seals and line up the pointer.

| |

| Pail

Racking Adapter |

|

Description - BetterBottle Pail Racking Adapters couple SimpleFlo

valves to any plastic pail, and the combination makes racking from a

pail into a BetterBottle carboy for secondary fermentation clean and

simple. Description - BetterBottle Pail Racking Adapters couple SimpleFlo

valves to any plastic pail, and the combination makes racking from a

pail into a BetterBottle carboy for secondary fermentation clean and

simple.

Operation - The

Pail Racking Adapter uses a Viton O-ring to make a tight, static

seal against the inside wall of a pail. Racking simply requires

opening the SimpleFlo valve, and letting gravity go to work - there

is no need for siphons or pumps. Usually, the Pail Adapter is

installed so that a level pail will drain to just above the expected

level of the sediment layer. If some usable liquid remains above the

sediment layer, the pail can be tipped slightly in order to recover

this liquid. For more detailed information about the use of the Pail

Adapter refer to the How-To

Tips tab to the left of this

page.

|

|

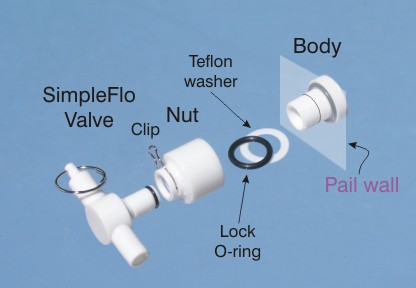

Installation - The

BetterBottle Pail Racking Adapter has been designed so it is easy to

install and service. Be certain all of the component parts are

installed in the correct order. Hold the body of the Pail Adapter in

place and install the Teflon slip washer and locking O-ring in that

order. Apply a little water to the threads and install the nut.

Finger tighten the nut, using enough force so the Pail Adapter makes

a good seal. A sticky pad (jar opener) can make tightening

easier.

|

|

Pail Racking Adapter

- Sequence of Components -

Note: SimpleFlo Valves are not included as part of

Adatpers, order them separately.

|

|

Most pails used for winemaking and brewing are

made of HDPE and it is easy to make a 3/4" (2 cm) hole in their

sides for a BetterBottle Pail Adapter.

|

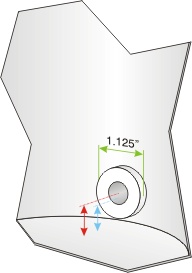

Refer to the figure to the right and

decide where to position the hole in the wall of the pail. The

depth of liquid (BLUE) left in a pail, when it is level and

drained through a Pail Adapter and SimpleFlo valve, will be

1/8" (0.3 cm) below the center of the hole (RED). The center

of the hole must be at least 3/4" (2 cm) above the bottom of

the pail so the wall can flex and seal with the Pail Adapter

O-ring. At this height, the residual liquid will be 5/8" (1.6

cm) deep. The sediment produced by most wine kits started in

30 liter pails is approximately that deep. If the center of

the hole in the pail is 1" (2.5 cm) above the bottom of the

pail, the residual liquid will be 7/8" (2.2 cm) deep. Because

the bottoms of pails vary in thickness and are usually

recessed, it is best to make the measurement for the center of

the hole from the inside of a pail and press a sharp pointed

tool through the wall to locate the

center from the outside. |

| A 3/4" hole saw or an electrician's

knock out punch will make a clean hole. Drill slowly with the

hole saw.

If you do not have these tools, you can

use an inexpensive (~$4.00) spade wood drill bit. Most

hardware stores stock the #88812 Irwin Speedbor bit or an

equivalent. The bit has a hex shank that will fit nicely into

an electric screwdriver. You can use a drill, but the low

speed of a screwdriver is ideal for this purpose. The bit has

points (See #1 arrows) that are the right length to just cut

through the wall of most pails before the broad part of the

bit begins to cut. Do not attempt to drill all the way

through. Once the points of the bit have cut through the wall,

you can press the plug (See #2) out of the hole and leave a

clean edge (See #3)

|

| |

| Cleaning /

Sanitizing |

|

The special PET from

which BetterBottle Carboy and Pail Adapters and SimpleFlo valves are

made has a non-porous, hydrophobic surface, making these parts

extremely easy to clean and sanitize. In theory, it should not be

necessary to remove and disassemble Carboy or Pail Adapters and

SimpleFlo valves to wash and sanitize them between batches, provided

care is taken to expose all of the internal parts to wash and

sanitizing solutions. However, a major advantage of BetterBottle

fittings is the ease with which they can be completely disassembled

and reassembled, so it makes good sense to spend the few extra

minutes it takes to be sure everything is absolutely clean and

sanitized. Prior to storage, rinse and dry everything

carefully.

BetterBottle Adapters and SimpleFlo valves may

be damaged by temperatures exceeding 75° C (167° F). Read the

Wash/Sanitize section, under the Technical tab

at the top of this page, for important informaton.

The PET is very tough and will not scratch

easily; however, use caution not to scratch the precision, smooth,

sealing surfaces of Carboy and Pail Adapters. Always rinse Adapters thoroughly in clean water before

storing them.

Abrasive scouring pads and cleansers should

never be required, or used.

Soaking metal parts in cleaning or

sanitizing solutions can cause corrosion - they should be

removed.

Service

- The adapters and SimpleFlo valves

are very rugged, but dropping them on a hard surface may cause them

to chip or crack, so take reasonable precautions. Should it be

necessary to remove the O-ring from the groove in an Carboy Adapter

body, do not use sharp tools that might cut the Teflon encapsulation

of the O-ring. Press a thumb nail down between the rim of the groove

and working your way around the groove, push the O-ring up and out

of the groove. In general, when removing O-rings take great care not

to scratch the walls or base of the O-ring grooves. Plain O-rings

can usually be removed rather easily by holding the fitting in one

hand with your thumb nail across the O-ring to keep it from moving

in the groove, while you push a wave of the O-ring toward

your nail to make a bulge that you can roll out of the groove. Use

only BetterBottle O-rings and washers for replacement; they are made

of special materials that cannot be easily obtained through hardware

suppliers and other materials may not function correctly.

If a SimpleFlo valve leaks at point #2, refer

to the SimpleFlo valve

tab to the left of this page for

service suggestions.

If

a SimpleFlo valve and Adapter assembly leaks at point #1, there are

a number of possible causes: 1) The large O-ring on the SimpleFlo

valve has been damaged or its groove is scratched or dirty (see the

SimpleFlo valve

tab to the left of this page for

pertinent service suggestions), 2) The bore of the Adapter is

scratched where it seals with the large O-ring on the SimpleFlo

valve, or 3) The Racking Adapter is not sealing against the inner

wall of the carboy or pail and liquid is creeping along the thread

of the Racking Adapter to the first point where it can escape, which

is at point #1.

The large O-ring on a SimpleFlo valve only

penetrates about 1 cm (0.4") into the bore of a Racking Adapter, so

it is easy to inspect the bore for scratches visually with good

lighting. For confirmation that the valve seals of a SimpleFlo valve / Carboy Racking Adapter assembly are

in good condition, use a hose to connect the stem of the Adapter to

a faucet and apply water pressure. A pressure of between 1 and 2 bar

(15 and 30 PSI) is recommended. Higher pressures may cause the valve

to pop out of the Racking Adapter. Open the SimpleFlo valve to let

the connecting hose fill with water and then close the valve, dry

off the parts, and check for leaks.

If the Racking Adapter is not sealing against

the inner wall of the carboy or pail, remove the Adapter and inspect

the sealing O-ring and its groove for nicks, scratches or debris.

Also, inspect the port in the carboy or pail. Is the hole round and

is it a close fit for the thread of the Adapter? Is the inner edge

of the hole smooth and free of burrs that might prevent a good seal?

In the event that there is no apparent cause for the leak at point

#1, carefully clean the inner surface of the carboy or pail around

the hole, rinse off the sealing O-ring and its groove, and reinstall

the Adapter (see above), making sure that the nut is sufficiently

tight.

|

| Part

Numbers |

|

Carboy Racking Adapter (SimpleFlo

Valve not included, order separately) - BB-ADAPT(RK)

Tool for installing Racking Adapter in 5

& 6 gallon BetterBottle carboys - BB-ADAPT(RK)-IT

Replacement locking O-ring, Teflon slip

washers, and pointer for Racking Adapter -

BB-ADAPT(RK)-SERV(A)

Replacement Teflon encapsulated O-ring for

Racking Adapter - BB-ADAPT(RK)-SERV(B)

Pail Racking Adapter (SimpleFlo Valve not

included, order separately) - BB-ADAPT(PL)

Replacement set of O-rings, and Teflon slip

washer for Pail Racking Adapter - BB-ADAPT(PL)-SERV

|

| Packaging |

|

BB-ADAPT(RK) -

Individually packed

in a hang-hole, zipper bag

Bags of 20

individual packages - 2.19 lbs (0.99 Kg)

BB-ADAPT(RK)-IT -

Individual parts are not packaged

Boxes of 88 parts - 18" X 6" X 4" (45.7 cm X 15.2 cm X

10.1cm) 11.5 lbs (5.22 Kg)

BB-ADAPT(PL) -

Individually packed in a

hang-hole, zipper bag

Bags of 20

individual packages - 1.03 lbs (0.47

Kg)

|

|